ITOCHU MACHINE-TECHNOS CORPORATION is a technique-oriented machinery trading company providing a total solution for “Textile & Paper Machinery”, “Machine Tools”, “Industrial Machinery”, or “Food & Pharma Machinery” field and is developing its businesses worldwide. Making the most of both technical capabilities, which is our advantage, and the latest information of the world gained through the ITOCHU group’s network, we are aiming at further development.

In addition to natural fibers, wide variety of high performance fibers have been researched and developed. The usage of textiles and Paper products are necessary among in wide variety of sections in the market, not only for clothings, but also for medicine, sanitary, lifestyle, natural disasters, securities, and environment.

We will select and suggest the best machineries for every customer from wide varieties of our product line up including functional synthetic fiber spinning, spinning, looming, knitting, dyeing/finishing, nonwoven, and also recycling. We are contributing to the foreign markets by exporting highly developed Japanese textile machineries.

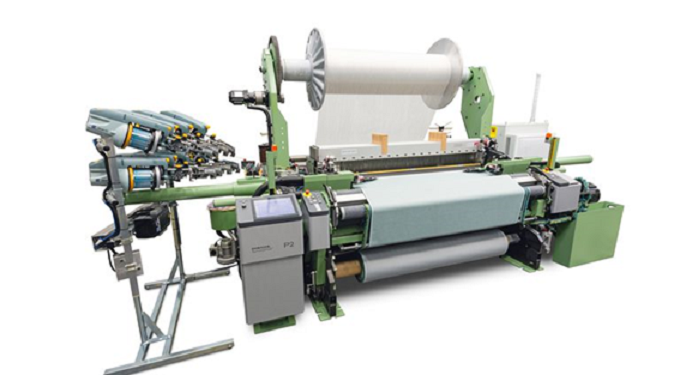

DORNIER is the manufacturer of the highest standard of weaving machines which was nurtured by German Meister and they are used in weaving mills all over the world. DORNIER starts its origin from the manufacturing of aircrafts, and many products from the highest brands and top-share companies in the market such as the airbag cloth for automobiles, industrial filters, glass fiber textiles, and high-performance fiber textiles are mostly made by DORNIER weaving machines. DORNIER machines also contribute to the highest brands of business suits, silk textiles, and also for Japanese traditional clothing, Kimono.

Truetzschler is the top manufacturer of machineries for paper and spinning. In the paper area, we handle high speed and high productivity machineries for interior materials of automobile, face masks and sterilization sheets for sanitary purposes, and many other paper products. In spinning area, we handle the spinning machines to make yarn for daily clothes we wear. Finally, Truetzschler is innovating its technology on production management by using IOTs and AIs. Truetzschlers’ long-term experience and achievements in paper and spinning area support its innovation at present and in the future.

Toyota Industries Corporation is founded in 1926. Its founder, Mr. Sakichi Toyoda researched and developed the automatic weaving machines in which astounded the weaving industries back then, and its corporate spirit and philosophy has been inheriting until today.

The new JAT810 has No.1 share in the market. Itochu Machine-Technos is providing the Toyota brand to the market world-wide.

Machine tools are also called “mother machine” in the meaning of “the machine for producing various machines”.

For example, an automobile consist of tens of thousands of parts and the machines that produce those tens of thousands parts are machine tools.

We deal with a lot of domestic or international machine tools taking advantage of cutting-edge technologies and are expanding our business in various corporations, including aircraft, semiconductor, and precision measuring equipment manufacturers as well as automobile companies. The business fields are also growing mainly in emerging countries. Quite simply, we are developing our business globally. We stretch from sales of various machine tools to domestic sales, export, import, and engineering services of whole systems including peripheral components.

We provide large machine tools to marine engine manufacturers. An engine for a large tanker, namely only a single component of parts weights as much as 100 tons. For larger machines, dimensions and superimposed load of a table for workpieces could reach 6 m x 25 m and 300 tons respectively.

Rivet joining technique is inevitable for manufacturing outer panels of aircrafts. Broetje produces a system where punching, inserting rivets, and caulking is conducted in an integrated manner. Recently, while reducing weight of aircrafts, composite materials are increasingly used and Broetje are focusing their effort on developing related equipment thereof.

Industrial machinery covers a wide range of machines including board making machine, metal/film/plastic/new material processing machine, semiconductor/liquid crystal related equipment, electronics related equipment, oil/chemical plant equipment, environment/recycling related equipment.

Industry Machinery division uses domestic and international state-of-art technologies and engineering capacity and offers breakthroughs and solutions.

This is a high-performance flexographic printing machine manufactured by UTECO whose headquarters is located in Verona, Italy and whose sales results are the best in various countries in the world. In Japan, gravure printing machines using organic solvent are the mainstream in the food/sanitary product packaging industries, etc. In Europe and U.S.A., flexographic printing machines that use environmentally-friendly water-based ink account for a large share. We have no doubt that flexographic printing machines using no solvent will attract attention and become widespread in the future in Japan in order to deal with residual solvents problem in food packaging and work environment problem of printing plants.

In a plant, steam boilers generally use fossil fuel including heavy oil, gas, or coal as a main heat source or for power generation. Use of fossil fuel resulting in emission of greenhouse gases such as carbon dioxide and subsequently leading to a big environmental load has become a problem in recent years. Woody biomass is one of reusable energies and does not increase carbon dioxide when burning. To propose using a woody biomass-fired boiler for a heat source or power generation means to make a great contribution for creating a material-cycle society and then realizing a sustainable world.

Optical Control Systems GmbH is the manufacturer that specializes in developing an inspection and analysis systems for plastic materials.

Not only Analyzer for pellet, powder and film but also Turnkey Lab Solutions.

It enables you to optimize, save labor costs and visualization of the inspection results by introducing the online system which is taking material samples during the ongoing production process and simultaneously, carring out the analyzing and sorting constantly.

Gneuss GmbH develops several types of Screen Changers for handling the demand of the customer.

The patented Rotary Filtration Systems and screen changers enable fully automatic, process and pressure constant filtration and, it is unnecessary to suspend the process even during screen chenges.

It is used for various applications, film/ sheet/ pipe/tube manufacturing line, compound, synthetic fiber etc.

The MRS Extrusion System which has an efficient degassing is installed for PET bottle recycling, sheet for food container and so on.

These machines are environmentally-friendly and able to contribute to the SDGs.

Many challenges and efforts are currently under the progress in the world in order to achieve “decarbonized society”.

The secondary battery is expected to play an important role in the various field, such as “the electric vehicle, “storage battery”, and other application.

Based on our long-standing project reference and experiences, in the battery field, we are expanding our sales promotion globally, and can offer not only the machine component, but also the total solutions for ” Lithium-ion battery”, as well as the “Next generation battery” such as “Solid State Battery”, “Fuel cell” and other types of battery.

Food Machinery Group provides total machinery solution, mainly imported, together with advanced engineering to both domestic and foreign customers who manufacture foods and pharmaceuticals. Highly experienced engineers shall provide after maintenance service locally together with spare parts supply. Various machineries are handled, for example, “filtration machine for beer”, “potato chips manufacturing machine”, “onion skin peeler”, “labor saving automation process”, “mineral water processing machine”, and so on. Especially “filtration machine for beer” and “potato chips manufacturing machine” are adopted by almost every domestic beer manufactures and potato chips customers.

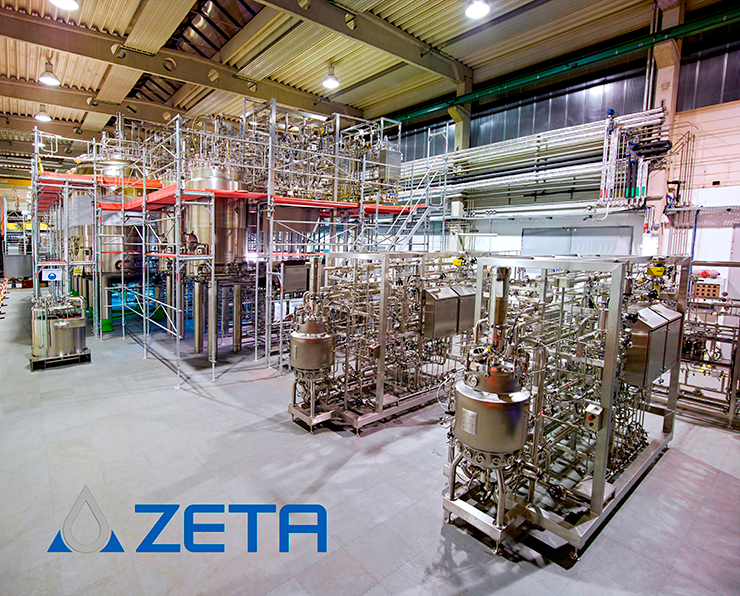

ZETA is having deep and wide knowledge of processes and process technology for biopharmaceuticals and provides total engineering solution such as Bioreactors & Fermentation Systems, Downstream Systems, Freeze & Thaw Systems, Freeze Container, etc. Systems are made by stainless steel to achieve reuse of system and there are a lot of installation history in biopharmaceutical customers in Europe. ZETA specializes in skid technology. The division of the processing system into discrete modules is already done in the engineering phase. Skid technology has the big advantage that the fabrication and assembly of the processing equipment can be done in ZETA factory at the same time as building works are in progress at the destination, which may be a greenfield or brownfield site. This substantially reduces the project completion time. The ZETA factory provides ideal conditions and facilities for manufacturing high-quality processing systems.

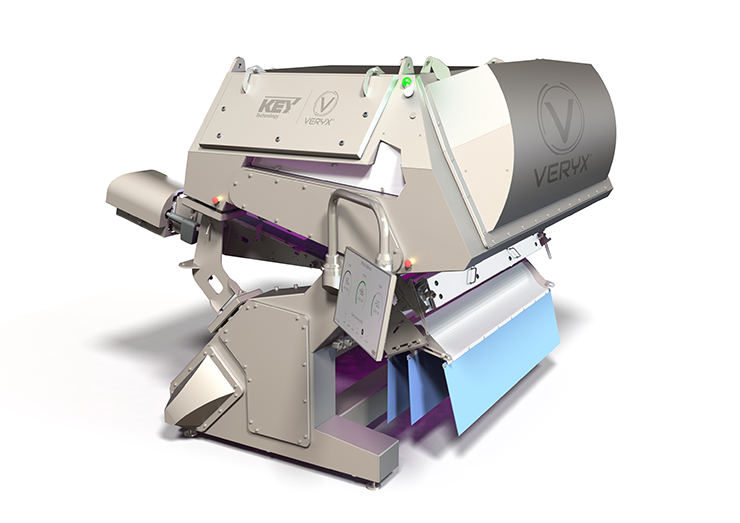

Key sorters provide superior sorting results as they detect and remove defects and foreign material (FM) based on color, structure, shape, size or biochemical characteristic differences in a single sorting pass. Processors around the world depend on Key Technology for sorting excellence. It is commonly used by pastry and frozen food industries to sort fruits and vegetables, nuts, dried fruit, fresh-cut produce and more. For example, it is used in the large scale production line of potato chips and archive to provide food safety.

We provide Technology & Engineering in order to fulfill our customers’ needs from basic planning to after sales services including: technical support for machinery sales; engineering & design work; pre-shipment inspection; various utility constructions; machine installation; commissioning & adjustment; operation instruction; supply of maintenance parts; inspection and maintenance of delivered machines; and troubleshooting.